Drummond-GCT™ Water Cooled Hood

- Mouth angle

- Hood / door configuration

- System draft

- Infiltration rate

- Apron plate/hood gap

- Door/hood gap

- Hood geometry

- Hood cooling system (panel design, water velocity)

- Downstream infiltration

- Physical condition of hood

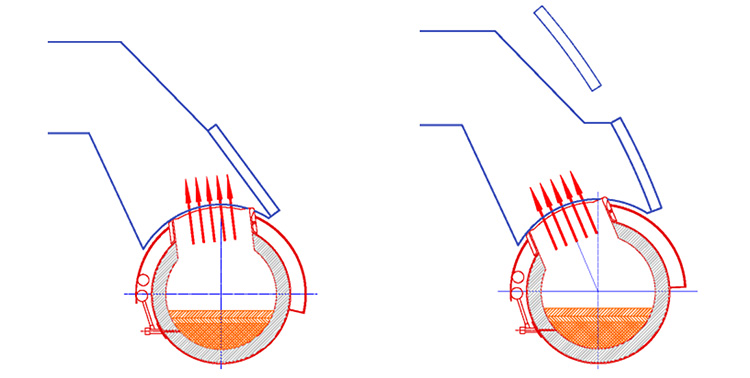

- Converter mouth blowing angle is too close to vertical

- Door/hood joint is blasted by hot gas

- Excessive gas leakage

- To prevent leakage, the system draft has to be increased; this results in excessive infiltration

- Water leaks (corrosion, erosion, insufficient water flow/velocity, crane impacts)

Moving the door joint out of the direct path of the process gas will improve gas capture.

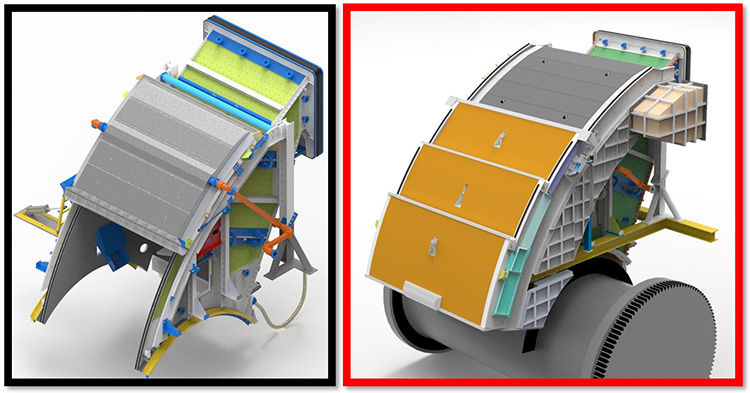

Design advantages of Drummond-GCT Hood Design:

- Simple, low cost fabrication

- Rugged, durable design

- Low maintenance costs

- No accretion build-ups

- Long panel life

- Easy installation

- Simple operation

- Closed circuit water system (minimizes evaporation and build-up of dissolved solids, reduces opportunity for oxygen entrainment minimizing internal corrosion)

Gas Cleaning Services

GCT provides gas cleaning services such as process gas handling, fugitive emission control, bulk material handling, and more.

Process Gas Handling &

Cleaning System Design

Fugitive Emission

Control

Drummond-GCT

Water Cooled Head

Process Vessel

Design

Existing Asset Life Cycle

Optimization

Process Evaluation &

Optimization

Bulk Material Handling

System Design

Water & Wastewater

Treatment

Project Development

Services

Technology Commercialization &

Integration

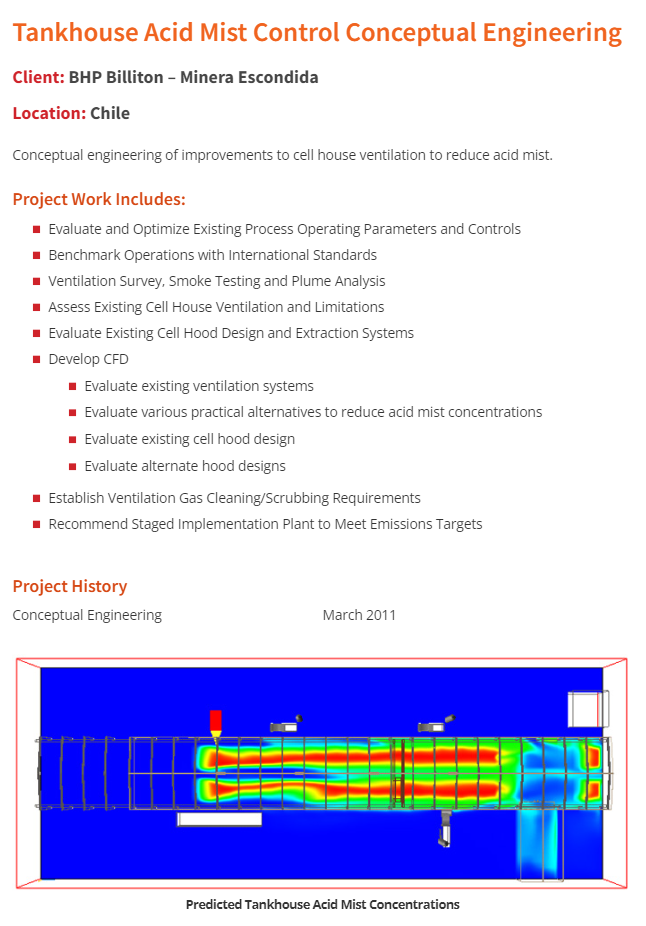

Computational Fluid

Dynamic Modeling

Energy

Services

GCT provides waste heat recovery solutions, plant energy audits, decarbonization roadmap development, and many more energy services.

Energy

Optimization

Waste Heat Recovery

Solutions

Plant Energy

Audits

Fuel Conversion

Solutions

Project Development

Services

Technology Commercialization &

Integration

Decarbonization Roadmap

Development

Hydrogen

Services

GCT is proud to provide hydrogen services for applications such as metallurgical reduction, industrial thermal heat, and power generation.

Hydrogen Technology

Development

Hydrogen Risk & Safety

Management

Hydrogen Technology

Integration & Implementation

Let's Make The World a Better Place, Together

Follow Us

GlossyFox Web Design